Element 119 industrial clear coatings for manufacturers treat nearly every type of surface and substrate. A few examples are:

Automotive Parts and Accessories: Flexible exterior trim, steel, and aluminum wheels, body panels, bumper and brake systems, hitches, shocks, axles, coil springs, under hood/body parts, windshields and windscreens. Our coatings also protect hydrographic printing used in the automotive and body plastic markets.

Aerospace: Composites like fiberglass and carbon fiber used in aerospace and automotive industries benefit from the high UV resistance, moisture/vapor barrier, and finish preservation. We also protect paintwork, gel coat, glass, and finished metal surfaces.

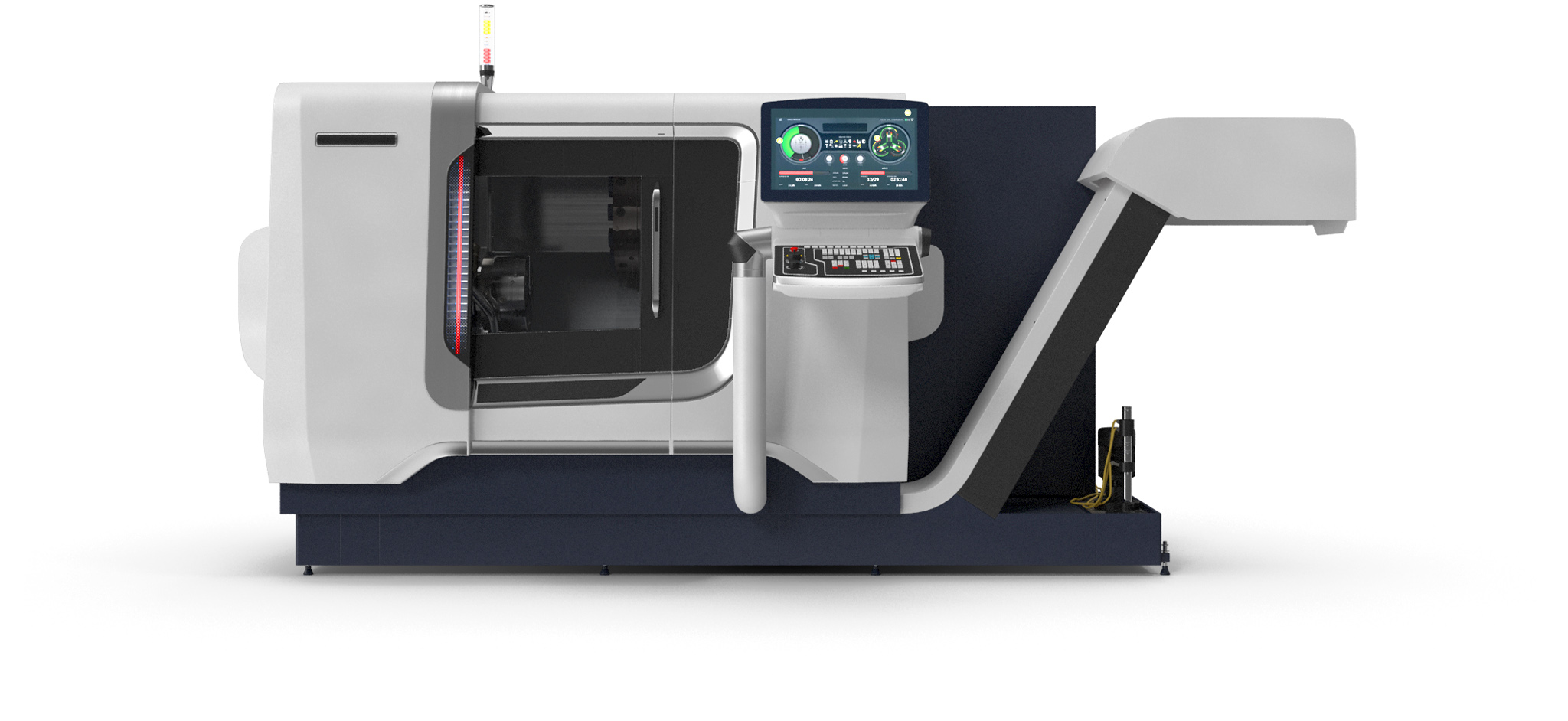

Industrial Vehicles: Agricultural equipment, construction machinery, trains, and support rescue vehicles.

Electronics: From mobile phones, laptops, computers, accessories, and GPS systems, lighting fixtures, and metal trim, to marine boating components, aviation controls, display components, and watches, we protect it all.

Sports and Recreation Equipment: Golf balls, fitness equipment, rackets, bicycles, motorcycles, outboard motors, and recreational vehicles.

High-Heat Applications: Stave off rust, corrosion, and dulling from metal surfaces with a high-heat clear coating to provide an effective barrier against vapor, moisture, and salts for bare or polished metals such as blasted steel, aluminum, brass, or other metal surfaces. Our clear coatings also provide a great finishing coating for engine components, barbeques, and HVAC components as well.

Interior Hardware: Furniture, fixtures, and door handles.

Surgical and Medical: Our autoclavable coatings are easy to clean and can be applied very thinly to satisfy tolerance requirements.

Physical Vapor Deposition (PVD) Process Replacement: Simplify your application from a multi-layer process to a single clear coating with high hardness, mar resistance, and high chemical resistance with UV stability.

Plastics: Our thin (.5-1mil) plastic coatings offer increased scratch and mar resistance with a high UV stability. These hard clear coatings have high adhesion to a variety of plastics with outstanding clarity.

Simplified application and curing processes, finished durability, quality, aesthetics, as well as applied cost efficiency are all requirements we meet for your successful finishing operation. Element 119’s innovative clear coating products enhance manufacturer’s revenue streams through their new aesthetics and enhanced performance properties.